The dream of a permanent human presence on the Moon, a bustling hub of science and exploration, hinges on one fundamental requirement: power. Without a reliable, persistent energy source, lunar outposts remain temporary campsites, limited by the batteries they can carry. The solution lies in establishing a robust lunar power grid, and the architects of this monumental project are not human, but highly advanced, autonomous robots. This endeavor represents a quantum leap in engineering, pushing the boundaries of what’s possible in the most unforgiving environment imaginable—the vacuum of space. Recent breakthroughs in deploying large-scale solar arrays in simulated lunar conditions are paving the way for this future, showcasing the incredible resilience and intelligence being built into the next generation of spacefaring machines. This isn’t just a story about solar panels; it’s about the sophisticated robotics and AI that must operate flawlessly where no human could.

This article delves into the immense technical challenges of constructing infrastructure in a vacuum, exploring the innovative robotic systems designed to overcome them. We will analyze the critical role of thermal vacuum testing, the materials science breakthroughs required for survival, and the artificial intelligence that serves as the brain for these lunar construction workers. From the latest in Robotics News to developments in AI Sensors & IoT News, the technology enabling a lunar grid has far-reaching implications, promising to revolutionize both space exploration and terrestrial industries.

Section 1: The Imperative for a Lunar Power Grid

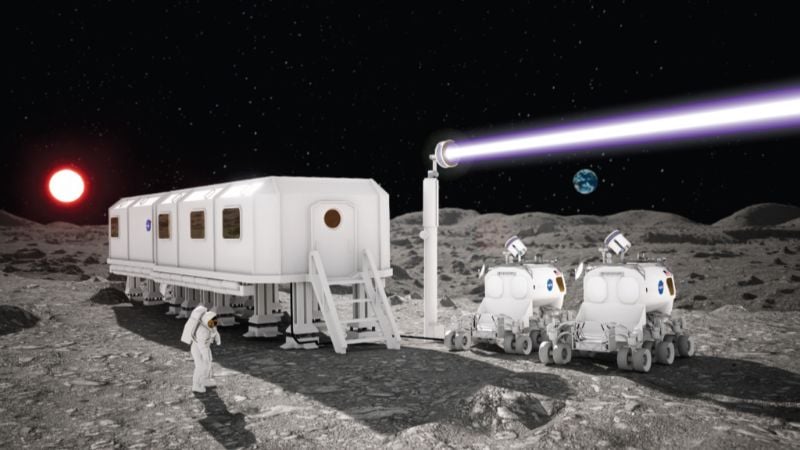

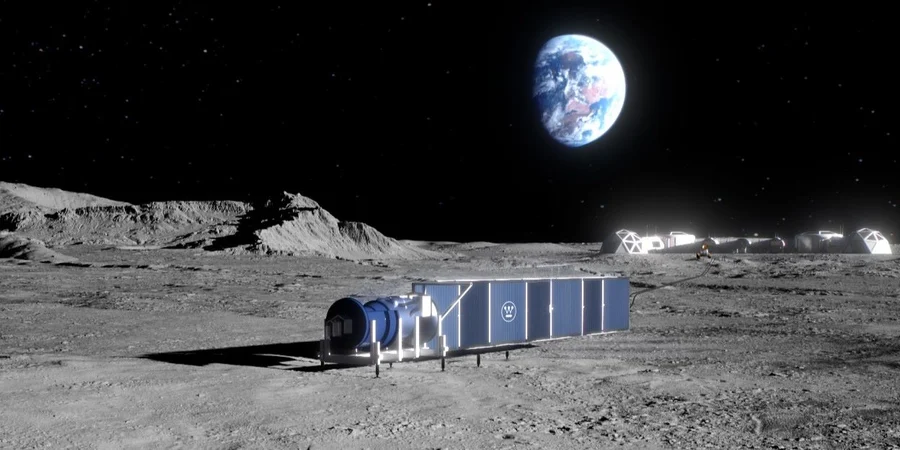

For decades, lunar missions have been short-duration sprints, constrained by the finite power supplies of landers and rovers. To transition from temporary visits to a sustainable presence—with habitats, in-situ resource utilization (ISRU) facilities, and long-term scientific experiments—we need a continuous and scalable power source. A lunar power grid, fed by vast solar arrays, is the most viable solution, but building it presents a challenge of astronomical proportions.

Why Astronauts Can’t Do It Alone

While astronauts are essential for complex, nuanced tasks, large-scale construction in the lunar environment is fraught with peril. The abrasive, electrostatically charged lunar regolith (dust) can damage equipment and pose a health risk. The extreme temperature swings, from a scorching 127°C (260°F) in sunlight to a cryogenic -173°C (-280°F) in shadow, place immense stress on spacesuits and tools. Furthermore, every hour of an astronaut’s extravehicular activity (EVA) is incredibly risky and expensive. The latest in Autonomous Vehicles News points to a clear trend: for tasks that are dangerous, repetitive, and require immense precision, autonomous robotics are the superior solution. These systems can work tirelessly for weeks or months, assembling and maintaining the infrastructure needed to support human life.

Vertical Solar Arrays: A Game-Changing Design

The concept for a lunar grid revolves around a novel approach: Vertical Solar Array Technology. Unlike the flat, ground-based panels used on Earth or on previous rovers, these are towering masts, ten meters or taller, that unspool solar blankets like window shades. This vertical orientation offers several key advantages. Firstly, it allows the arrays to track the low-hanging sun near the lunar poles, maximizing power generation throughout the long lunar day. Secondly, the vertical design minimizes the accumulation of problematic lunar dust, which can quickly coat and disable horizontal panels. The deployment of these massive structures, however, requires a robotic system of unprecedented reliability. This system must be able to autonomously unpack itself from a compact, stowed configuration, erect a towering mast, and deploy the solar panels with perfect precision—all without human intervention.

Section 2: Engineering for the Void: The Gauntlet of Thermal Vacuum

Before any hardware is sent to the Moon, it must first survive Earth’s most rigorous simulations of the lunar environment. The centerpiece of this testing is the thermal vacuum (TVAC) chamber—a massive, sealed vessel where the air is pumped out to create a near-perfect vacuum and powerful lamps and cryogenic shrouds simulate the extreme temperature cycles of space. Successfully passing TVAC testing is a non-negotiable milestone, revealing design flaws that would be catastrophic on the Moon.

The Physics of Failure: Heat, Cold, and Outgassing

Operating machinery in a vacuum is fundamentally different from on Earth. Here, the primary challenges are thermal management, material stability, and mechanical friction.

- Thermal Management: On Earth, excess heat from motors and electronics is carried away by air convection. In a vacuum, this is impossible. Heat can only be dissipated through conduction (direct contact with a colder surface) or radiation (emitting infrared energy into space). Engineers must design intricate thermal pathways, using heat pipes and radiators to channel waste heat away from sensitive components. Without this, electronics would quickly overheat and fail. This is a critical area of research, influencing everything from space robotics to future AI Edge Devices News, where managing heat in compact forms is paramount.

- Material Science and Outgassing: The vacuum of space is a hostile environment for many materials. Adhesives, plastics, and lubricants can “outgas,” releasing trapped volatile compounds. This process can cause the materials themselves to become brittle and fail, and the released gases can condense on sensitive surfaces like camera lenses or solar cells, rendering them useless. Every component must be made from space-grade materials specifically chosen for their low-outgassing properties.

- Lubrication in a Void: Conventional oils and greases would simply boil away in a vacuum. Mechanical joints, gears, and bearings in a robotic deployment system require specialized lubrication to function. The solution often lies in solid-film lubricants like molybdenum disulfide or tungsten disulfide, which are applied as a thin coating to metal surfaces. Another option is vacuum-rated greases with extremely low vapor pressure, ensuring they remain stable across the full lunar temperature range.

A Case Study: The Robotic Deployment Mast

Consider the robotic mast designed to deploy a vertical solar array. This system is a marvel of mechatronics. It consists of high-torque electric motors, precision gearboxes, and a complex, interlocking mast structure. During TVAC testing, engineers monitor hundreds of data points. Sensors track the temperature of every motor, the strain on each structural element, and the power draw during deployment. High-resolution cameras, a key component in AI-enabled Cameras & Vision News, watch for any sign of mechanical binding or misalignment. The test cycles the system from extreme cold to extreme heat, commanding it to deploy and retract repeatedly to simulate its entire operational life on the Moon. A single motor failure, a gear tooth seizing, or a structural component warping beyond its tolerance means a complete redesign.

Section 3: The AI Brains Behind the Brawn

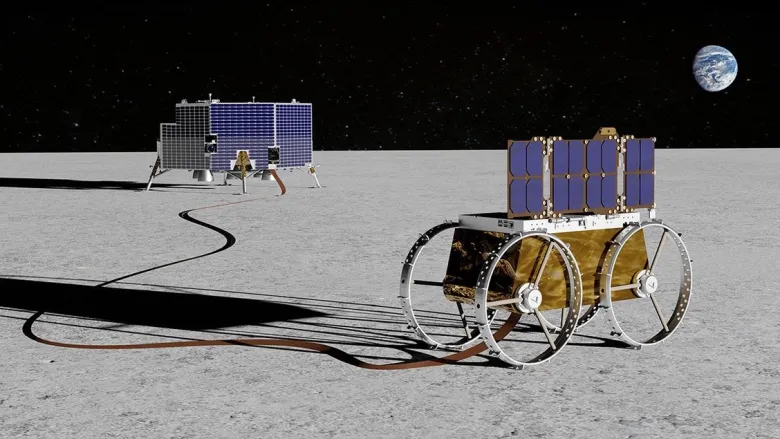

While the physical hardware is a feat of engineering, it is the sophisticated software and artificial intelligence that bring the system to life. The goal is not just automation but true autonomy—the ability for the system to make decisions, diagnose problems, and recover from errors without real-time commands from Earth, which can be delayed by several seconds.

From Deployment to Grid Management

The AI’s role begins the moment the lander touches down. Using a suite of sensors, including inclinometers and vision systems, the AI first assesses the local terrain to ensure the deployment base is stable. The deployment sequence is not a simple, pre-programmed routine; it’s a dynamic process. The system’s AI Monitoring Devices constantly check for feedback. For example, if a motor’s current spikes, the AI knows it’s encountering unexpected resistance. It might pause, slightly retract the mast, and then try again—a process akin to gently wiggling a stuck key. This level of intelligence prevents the system from breaking itself by applying brute force.

Once deployed, the AI’s job shifts from construction to operation. It becomes a key node in the nascent lunar grid, a topic closely related to advancements in Smart City / Infrastructure AI Gadgets News. The AI will:

- Track the Sun: Continuously orient the solar arrays for maximum energy absorption.

- Manage Power: Regulate the flow of electricity to batteries and connected habitats or experiments.

- Perform Health Checks: Regularly run diagnostics on its own motors, sensors, and electrical systems, predicting potential failures before they occur. This predictive maintenance is a hot topic in AI for Energy / Utilities Gadgets News.

- Communicate: Network with other power units to create a resilient, self-balancing grid, rerouting power automatically if one unit goes offline.

Practical Example: An AI-Handled Anomaly

Imagine a scenario where a micrometeoroid strikes a latch mechanism, preventing a solar blanket from fully deploying. A simple automated system would fail. An autonomous AI, however, would handle it differently.

- Detection: The AI’s vision system, powered by the latest in AI Cameras News, compares the current state to its expected model and detects the panel is misaligned. Simultaneously, tension sensors in the deployment cables report an anomaly.

- Diagnosis: The AI cross-references the data. It halts deployment to prevent damage and runs a diagnostic routine, isolating the problem to the specific latch.

- Corrective Action: It attempts a series of pre-programmed recovery actions. It might try to “shake” the mast gently or cycle the latch motor back and forth to dislodge any debris.

- Reporting and Adaptation: If recovery fails, the AI doesn’t give up. It calculates the reduced power output from the partially deployed panel, reconfigures the grid’s power budget, and sends a detailed error report to mission control. The system continues to operate at reduced capacity instead of failing completely. This resilience is the hallmark of a truly intelligent system.

Section 4: Implications, Recommendations, and the Future

The development of robotics capable of surviving and working in a vacuum is a cornerstone technology for the future of space exploration. The lessons learned and technologies perfected are not confined to the Moon; they have profound implications for future missions to Mars and beyond, as well as for numerous industries right here on Earth.

Pros, Cons, and Future Directions

The primary advantage of this robotic approach is its ability to build critical infrastructure safely and cost-effectively, enabling a new era of science and exploration. The main challenge, or “con,” is the immense complexity. These systems must have near-perfect reliability, as there is no easy way to service them. Future development should focus on several key areas:

- Enhanced Modularity: Designing systems with interchangeable parts that could potentially be replaced by another robot, a concept that could one day lead to self-repairing infrastructure. This could even influence the design of future modular AI Phone & Mobile Devices News.

- Greater Autonomy: Reducing the reliance on Earth-based oversight by developing AI that can handle a wider range of unexpected scenarios, drawing inspiration from the rapidly advancing field of AI Assistants News.

- Advanced Materials: Researching new composites and alloys that are lighter, stronger, and more resistant to the extreme lunar environment.

Terrestrial Spin-Offs

The technology driving lunar construction has numerous potential applications on Earth. The advanced, vacuum-rated robotics could be adapted for handling hazardous materials in sealed industrial environments. The AI-driven diagnostic and power management software could be used to create more resilient and efficient terrestrial power grids. The lightweight, high-strength materials could find their way into aviation or automotive manufacturing. Even the precision control systems could influence future AI Personal Robots or advanced manufacturing arms. The push into space consistently yields innovations that improve life on our own planet.

Conclusion: Building a New World, One Robot at a Time

The successful testing of robotic systems designed to build a power grid in a simulated lunar vacuum is more than just an engineering milestone; it is a tangible step toward humanity’s multi-planetary future. It demonstrates that we can overcome the immense challenges of building in off-world environments through intelligent and resilient autonomous systems. These robotic pioneers are not merely tools; they are the vanguard, preparing a new world for human arrival. The convergence of advanced robotics, AI, and materials science showcased in these projects is laying the foundation, not just for a lunar base, but for a future where the boundary between the possible and the impossible is redrawn. The latest Robotics Vacuum News is not about cleaning floors, but about cleaning the path for humanity’s next giant leap.