The Dawn of a New Innovation Era: AI in Product Research and Prototyping

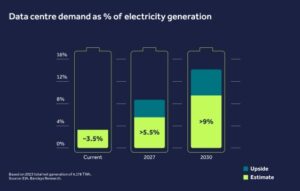

In the relentless race to innovate, the traditional product development lifecycle—a linear, time-consuming, and often wasteful process of ideation, design, physical prototyping, and testing—is being fundamentally disrupted. The culprit and catalyst of this transformation is Artificial Intelligence. No longer confined to the digital realm of software and services, AI is now a formidable partner in the tangible world of physical product creation. This evolution marks a pivotal shift in how we conceive, design, and validate everything from the intricate chassis of a delivery drone to the sustainable packaging of everyday consumer goods. This is the new frontier of AI Research / Prototypes News, where algorithms and data are forging the next generation of physical products.

AI is moving beyond mere optimization to become a creative collaborator. It empowers engineers and designers to explore solution spaces that are beyond human intuition, simulate real-world conditions with unprecedented accuracy, and embed sustainability into the very DNA of a product from its earliest stages. This article delves into how AI is revolutionizing research and prototyping, accelerating innovation cycles, reducing environmental impact, and shaping the future of industries from consumer electronics and robotics to automotive and healthcare.

The AI-Powered Blueprint: Redefining Design and Material Innovation

The initial stages of product development—conceptual design and material selection—have historically been guided by experience, established principles, and a degree of trial and error. AI is injecting a powerful dose of data-driven intelligence into this creative process, enabling the design of objects and the discovery of materials that were previously unimaginable.

Generative Design: Beyond Human Intuition

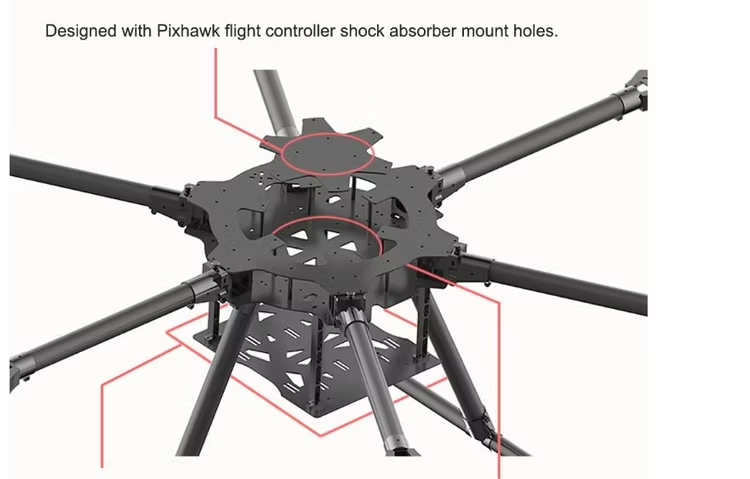

Generative design represents a paradigm shift from traditional computer-aided design (CAD). Instead of a designer drawing a specific shape, they define a problem by inputting a set of goals and constraints. These can include parameters like weight limits, material types, manufacturing methods, stress loads, and cost targets. The AI algorithm then explores thousands, or even millions, of potential design permutations, often producing organic, lattice-like structures that are highly optimized for performance and material efficiency. This process mimics nature’s evolutionary approach to design, resulting in solutions that are frequently lighter, stronger, and more efficient than what a human engineer might conceive.

A prime example can be found in the latest Robotics News. When designing a new robotic arm or the chassis for a next-generation Robotics Vacuum, engineers can use generative design to create a frame that is exceptionally lightweight for better battery life and agility, yet robust enough to withstand operational stresses. Similarly, in the world of Drones & AI News, companies are using these techniques to design drone frames that maximize flight time and payload capacity by shedding every unnecessary gram of material without compromising structural integrity.

AI in Material Science: Discovering Tomorrow’s Materials

The materials that make up a product are just as critical as its design. AI is accelerating the field of material science by enabling “in silico” discovery—predicting the properties of novel materials before they are ever synthesized in a lab. Machine learning models, particularly Graph Neural Networks (GNNs), can analyze the atomic structure of compounds to predict their characteristics, such as conductivity, strength, flexibility, and thermal resistance. This dramatically reduces the time and cost associated with discovering and testing new materials.

This has profound implications across numerous sectors. For instance, in the realm of Health & BioAI Gadgets News, AI can help identify new biocompatible polymers for medical implants. In wearable technology, covered by AI in Fashion / Wearable Tech News, it can lead to the creation of smart fabrics with embedded sensors that are both durable and comfortable. For developers of AI Edge Devices, this means discovering new semiconductor materials that are more power-efficient, pushing the boundaries of what’s possible in on-device processing.

From Pixels to Prototypes: The Rise of AI-Driven Simulation

Physical prototyping is one of the most resource-intensive stages of product development. Creating multiple physical iterations is expensive, slow, and generates significant waste. AI-powered simulation and digital twins are making it possible to conduct extensive testing in a virtual environment, refining designs to near-perfection before a single physical part is manufactured.

The Power of Digital Twins in Complex Systems

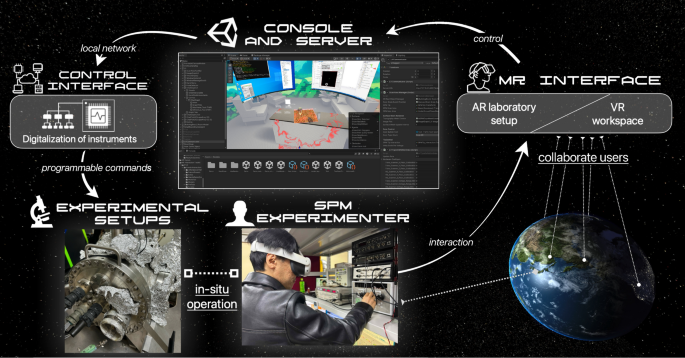

A digital twin is a dynamic, virtual replica of a physical asset, system, or process. What elevates it beyond a simple 3D model is its connection to real-world data, often supplied by a network of sensors covered in AI Sensors & IoT News. AI enhances digital twins by enabling predictive analytics. By feeding the twin real-time and historical performance data, AI algorithms can simulate future states, predict potential failures, and test operational changes without any real-world risk.

This technology is central to the latest Autonomous Vehicles News. Automakers create highly detailed digital twins of their vehicles and their sensor suites, including components featured in AI-enabled Cameras & Vision News. They can then run these virtual vehicles through billions of miles of simulated driving scenarios, exposing the AI driving system to a vast range of weather conditions, traffic patterns, and edge cases—a feat impossible to replicate safely and quickly in the real world. This same principle applies to optimizing the movements of AI Personal Robots on a factory floor to avoid collisions and maximize efficiency.

Advanced Simulation for Consumer Goods

On a smaller scale, AI simulation is transforming the development of consumer products. Consider the design of new Smart Appliances. Engineers can simulate the airflow inside a new oven to ensure even cooking or model the thermodynamic efficiency of a refrigerator design, making thousands of virtual adjustments to optimize performance. For products in AI Audio / Speakers News, AI can simulate the acoustic properties of different enclosure shapes and materials to achieve the perfect sound profile.

This approach directly addresses the challenges faced in packaging design. Instead of performing dozens of physical drop tests, a company can use AI-enhanced physics simulations to model how a new package design will withstand the rigors of shipping. The AI can simulate impacts from various angles and heights, analyze stress points, and suggest structural reinforcements, all within a matter of hours. This accelerates the design cycle, reduces material waste from broken prototypes, and leads to more robust and reliable packaging.

Engineering a Greener Future: AI for Sustainability and Recyclability

As consumer and regulatory pressure for sustainability mounts, companies are increasingly focused on the entire lifecycle of their products. AI is emerging as a critical tool for designing for a circular economy, enabling developers to assess and optimize the environmental impact of their products from the earliest concept stages.

![Delivery drone chassis - X500 Frame (CNC) [Digital File] - 3D Printing & Home Delivery Services](https://aigadget-news.com/wp-content/uploads/2025/12/inline_a092fb05.png)

Assessing Recyclability and Environmental Impact

One of the most significant challenges in creating a circular economy is designing products that can be easily and economically recycled. AI is providing powerful new tools to tackle this problem. AI vision systems can analyze a 3D model or even a simple sketch of a product and predict its recyclability score. The model can identify potential issues, such as the use of mixed materials that are difficult to separate, the presence of problematic adhesives, or labels that contaminate the recycling stream. This allows designers to make informed choices that improve a product’s end-of-life prospects.

Furthermore, AI is streamlining the complex process of Life Cycle Assessment (LCA), which evaluates the environmental footprint of a product from raw material extraction to manufacturing, use, and disposal. By automating data collection and analysis, AI can deliver LCA insights in a fraction of the time, giving R&D teams actionable data on the carbon footprint, water usage, and pollution potential of different design choices. This is impacting everything from the next generation of AI Kitchen Gadgets to the disposables used in AI Pet Tech News.

Optimizing for a Circular Economy

True sustainability goes beyond recycling; it involves designing products for longevity, repairability, and disassembly. AI can assist in this process by generating designs that use modular components, standardized fasteners, and easily separable materials. Imagine an AI Assistant for a repair technician, which uses augmented reality (a key topic in AR/VR AI Gadgets News) to overlay instructions onto a device. That AI system works best when the product itself was designed by another AI to be easily serviceable in the first place, creating a virtuous cycle of design and maintenance.

The AI Research Frontier: From Lab Prototypes to Everyday Gadgets

The impact of AI in R&D is not theoretical; it is already being felt across a vast spectrum of industries, shaping the devices we use every day and the technologies of tomorrow.

Real-World Applications Across Industries

- Smart Home and Wearables: In the world of Smart Home AI News, generative design is used to create aesthetically pleasing and thermally efficient casings for smart speakers and hubs. For the latest Wearables News, AI helps model the ergonomics of AI Fitness Devices for maximum comfort and sensor contact, while also simulating battery performance to extend life for devices like those in Smart Glasses News.

- Healthcare and Accessibility: AI is being used to design custom-fit prosthetics and orthotics based on patient scans. The latest AI for Accessibility Devices News highlights prototypes of smart canes that use AI-optimized sensor placements for better environmental awareness.

- Entertainment and Creativity: The principles of generative design are even entering the creative fields. As seen in AI Toys & Entertainment Gadgets News, AI can help design unique and complex toy components. In gaming, AI tools can generate vast, varied landscapes or character models, influencing the future of AI in Gaming Gadgets News.

- Mobile and Office: The very design of your smartphone is influenced by AI, which simulates antenna performance and thermal dissipation. This is a constant theme in AI Phone & Mobile Devices News. Similarly, AI Office Devices are being prototyped for better ergonomics and energy efficiency.

Best Practices, Pitfalls, and The Road Ahead

While the potential is immense, adopting AI in physical product R&D comes with challenges.

- Common Pitfalls: A significant risk is the “reality gap,” where simulations, no matter how advanced, fail to capture the full complexity of the real world. Over-reliance on AI without sufficient physical validation can lead to product failures. Additionally, AI models trained on biased or incomplete data can perpetuate flawed designs.

- Best Practices: The most successful approach is “human-in-the-loop,” where AI acts as a powerful collaborator that augments, rather than replaces, the expertise of human engineers and designers. It’s crucial to invest in robust validation processes that combine both virtual and physical testing to bridge the reality gap.

- The Future: The trajectory is pointing towards even deeper integration. We are seeing early Neural Interfaces News that could one day allow designers to interact with generative design tools more intuitively. The ultimate goal for many is the development of autonomous AI design agents that can take a high-level product concept and manage the entire R&D process, from material selection and design to simulation and sustainability analysis, presenting a final, validated blueprint for manufacturing.

Conclusion: The Co-Creation of Our Physical World

The integration of Artificial Intelligence into product research and prototyping is more than an incremental improvement; it is a fundamental re-architecting of how we innovate. By leveraging AI, companies can design better, more efficient, and more sustainable products at a speed that was previously unimaginable. From the complex systems in Autonomous Vehicles to the smart sensors in our cities, AI is the silent partner in the design process. The key takeaway is that AI’s role is not to supplant human creativity but to amplify it. It handles the complex calculations, explores millions of possibilities, and provides data-driven insights, freeing human designers and engineers to focus on the bigger picture: solving real-world problems. The future of our physical world will be built on this powerful synergy between human ingenuity and artificial intelligence.