We need to talk about the dirty work.

Everyone is losing their minds right now because a humanoid robot can fold a shirt or make a mediocre cup of coffee. That’s cool, I guess. But while the tech press is fawning over bipedal androids that walk like they’ve had too much tequila, there’s a revolution happening in the darkest, nastiest corners of industrial infrastructure. I’m talking about oil tanks.

Specifically, the automated cleaning of them.

I was reading a report the other day about the shift in refinery maintenance protocols over the last two years, and it hit me: the most valuable robots aren’t the ones mimicking humans. They’re the ones doing the jobs that kill humans.

For decades, cleaning a crude oil storage tank was basically a suicide mission with a paycheck. You drain the tank, but there’s always this thick, toxic sludge left at the bottom. It’s viscous, it’s full of hydrocarbons, and it releases gases that can knock you out before you even realize you’re dizzy. Historically, we sent guys in suits with shovels to manually scoop this stuff out. In the dark. Surrounded by explosive fumes.

It’s insane that we were still doing that in the 2020s.

The Industrial Roomba on Steroids

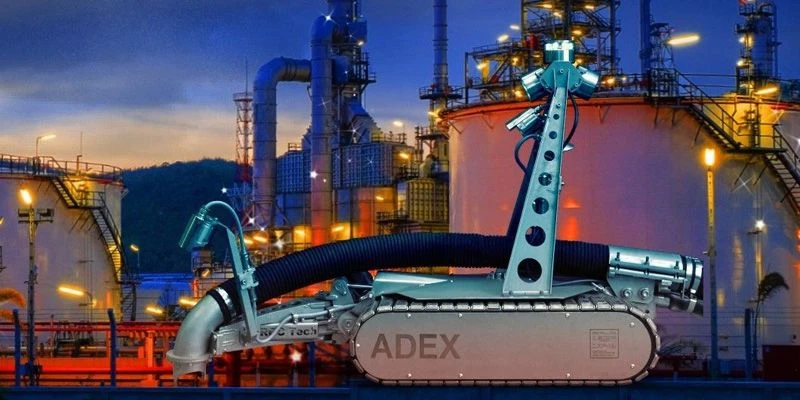

The concept that’s finally taken over—and we’re seeing this tech mature rapidly here in 2026—is essentially a vacuum cleaner. But calling it a vacuum cleaner is like calling a tank a heavy car. These are hydraulic or pneumatic crawlers designed to wade through sludge that would snap a normal axle in two seconds.

I’ve been following a few firms out of India, specifically around the Bengaluru tech hub, that really pushed this forward a few years back. The engineering challenge is wild when you think about it. You can’t use standard electric motors because a single spark turns the refinery into a crater. Everything has to be explosion-proof (Ex-proof).

So, you end up with these localized, remote-operated rovers. They don’t look like C-3PO. They look like boxes with treads and a massive intake nozzle.

The mechanics are brutally simple, which is why they work. The robot enters the tank (usually through a manway), navigates the floor, and uses high-powered suction to liquefy and pump out the sludge. It’s a closed loop. The sludge goes out, gets separated, and the oil goes back into the system. No guy with a shovel. No exposure to benzene.

Why Did This Take So Long?

Honestly? I think we just didn’t care enough about the safety stats for a long time. Or maybe the robotics weren’t robust enough to handle the viscosity.

Moving sludge isn’t like vacuuming dust. This stuff is heavy. It’s like trying to suck up cold peanut butter through a straw, except the peanut butter is toxic and flammable. Early attempts at these robots kept getting stuck or clogged. I remember hearing about a pilot program in 2022 where they had to send a human in to rescue the robot that was supposed to replace the human. Irony at its finest.

But the hydraulics have improved. The navigation systems have gotten better too. You can’t use standard cameras down there—it’s pitch black and covered in oil. The newer units use a mix of sonar and tactile feedback to map the tank floor. They know where the walls are, they know where the sludge piles are, and they just grind away at it until the floor is clean.

The Economics of “Zero Entry”

Safety is the headline, but money is the reason this tech is standardizing now.

Shutting down a tank for cleaning is expensive. Every hour that tank is offline, the refinery is losing storage capacity. Human crews are slow. They need breaks, they need ventilation setups, they need permits, and they can only work in short shifts because of the physical toll.

A robot? It doesn’t care. It doesn’t need fresh air. It doesn’t get tired. It can run 24/7 until the job is done.

I spoke to a maintenance manager at a mid-sized refinery last month, and he told me that switching to robotic tank cleaning cut their downtime by about 40%. That is a massive number in this industry. We’re talking millions of dollars in saved operational time.

Plus, you can recover more oil. The manual process often involved a lot of waste. These vacuum systems are designed to recirculate and recover hydrocarbons that would otherwise be tossed out as hazardous waste. It’s an efficiency play disguised as a safety play.

The Tech Stack in 2026

Here’s what’s interesting about the current generation of these machines. They aren’t autonomous in the way a self-driving car is. They don’t make complex moral decisions. They are tethered, usually, because wireless signals don’t penetrate thick steel tanks very well, and you need a heavy-duty line to pump the sludge out anyway.

But the operator interface has changed. It used to be a guy with a joystick staring at a grainy screen. Now, we’re seeing digital twins of the tanks. The operator sits in a control van outside the blast zone, looking at a 3D representation of the tank floor generated in real-time by the robot’s sensors. They click a sector, and the robot goes to work.

It’s boring. It’s unsexy. It’s just a dot moving on a screen removing gray blobs.

And that’s exactly what robotics should be.

We Need More “Boring” Robots

I get annoyed when I see billions of dollars poured into making robots that look like us. Humans are a terrible form factor for most industrial jobs. We’re squishy, we have bad balance, and we break easily.

The tank cleaning robots prove that form should follow function. A low-profile crawler with massive torque is infinitely better at cleaning a tank than a humanoid holding a vacuum cleaner.

There’s a lesson here for the rest of the robotics industry. Stop trying to replicate the worker. Replicate the *work*. If the work is “remove sludge,” build a sludge-eater. If the work is “carry boxes,” build a motorized pallet (which we did, and it works great).

So yeah, while everyone else is waiting for their robot butler, I’m cheering for the little hydraulic tank-crawlers. They’re saving lives, saving money, and cleaning up the mess we made. That’s the kind of future I signed up for.