The Invisible Shift in Sensor Tech

I was recently debugging a sensor array for a smart HVAC system when I realized just how clunky our current “micro” technology actually is. We talk about miniaturization constantly, but most commercial sensors I install or review are still visible to the naked eye. They require power sources, copper wiring, and protective casings that bulk them up. But I’ve been tracking a development that makes standard MEMS (Micro-Electro-Mechanical Systems) look like ancient machinery. We are finally moving into the era of sensors that are literally smaller than a grain of sand, printed directly onto the tips of optical fibers.

For years, I’ve followed AI Sensors & IoT News, waiting for the moment when hardware would catch up to the processing power of our algorithms. We have the AI models to interpret complex data, but we haven’t always had the physical ability to place sensors in the most critical, tightest spaces. That changes with the maturation of 3D-printed glass sensors. This isn’t just about making things smaller; it’s about fundamentally changing where we can gather data.

I want to break down why this specific intersection of photonics, 3D printing, and AI is the most significant hardware shift I’ve seen in 2025, and why I believe it will redefine everything from medical diagnostics to industrial monitoring by 2026.

Why Glass on Fiber Beats Silicon on Copper

Most of the sensors I work with rely on electricity. You have a transducer that converts a physical phenomenon (like heat or pressure) into an electrical signal. This works fine for your thermostat or your phone, but it fails miserably in harsh environments. Electrical sensors are susceptible to electromagnetic interference (EMI), they can spark (a bad idea in a fuel tank), and they degrade under high radiation or extreme heat.

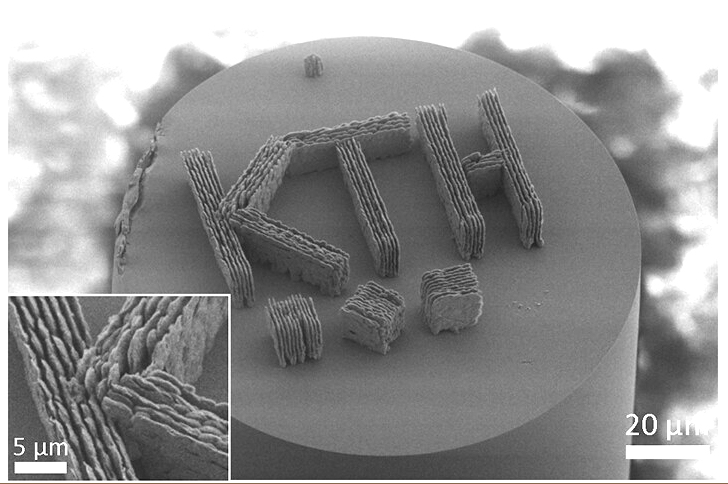

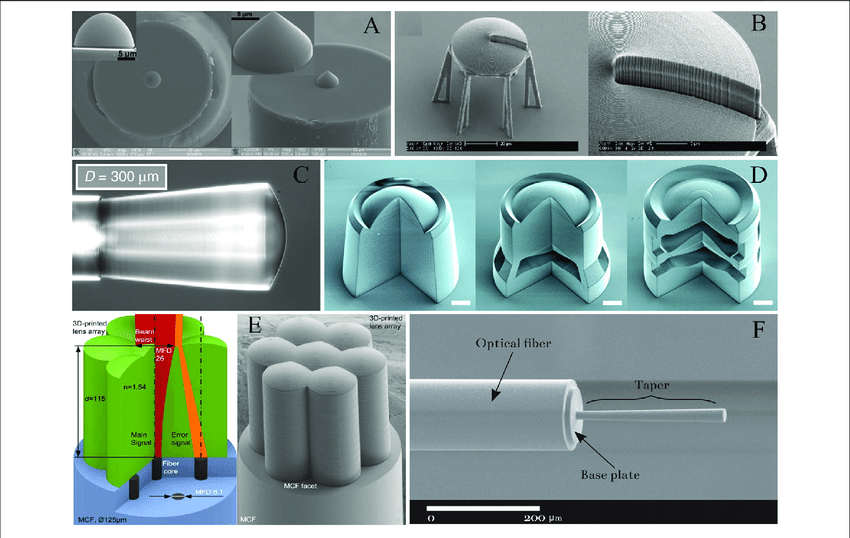

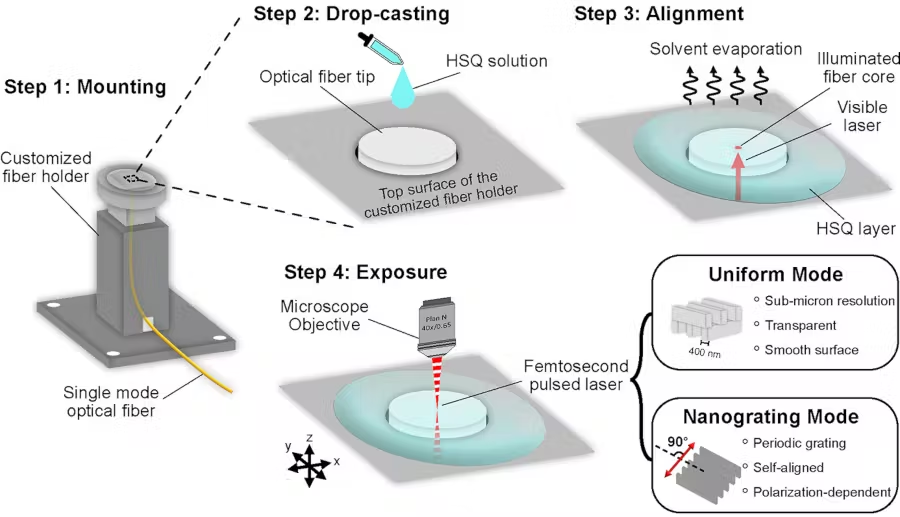

The tech I’m seeing now involves using multi-photon polymerization to 3D print microscopic structures directly onto the tip of an optical fiber. We are talking about structures huge distances smaller than a human hair. Because they are made of glass (silica) and use light instead of electricity to transmit data, they are immune to EMI and chemically inert.

I recently looked at specs for a prototype setup where the sensor was measuring temperature inside a corrosive chemical reaction. An electrical sensor would have dissolved or shorted out. The glass sensor just sat there, bouncing light back up the fiber, providing real-time data with zero degradation. For those of us following AI Monitoring Devices News, this is the holy grail: a sensor that can survive where silicon dies.

The Manufacturing Magic

The process fascinates me. It uses a femtosecond laser—that’s a laser pulsing at one quadrillionth of a second—to solidify a liquid polymer or glass precursor. The precision is insane. I’ve seen diagrams where they print complex spring systems or resonant cavities that fit entirely on the cross-section of a fiber optic cable (which is about 125 microns wide).

This allows for customization we couldn’t dream of before. If I need a sensor that only detects a specific frequency of vibration in a drone motor, I don’t have to buy a generic accelerometer and filter the data. I can theoretically print a mechanical structure that physically filters that frequency before the data even hits the AI model. This hardware-level preprocessing is a massive efficiency booster for AI Edge Devices News.

The Role of AI: Decoding the Light

Here is where the software side kicks in, and it’s where I spend most of my time. Optical sensors are incredibly sensitive, but they are also noisy. A slight bend in the fiber or a shift in ambient temperature can alter the light signal. In the past, this made fiber optic sensing expensive and complex because you needed high-end interrogators to make sense of the noise.

Now, I use machine learning models to handle the signal processing. We are seeing a surge in AI Research / Prototypes News where lightweight neural networks are trained to interpret the specific interference patterns (interferometry) returning from these micro-sensors.

I tested a setup recently where an AI model was trained to distinguish between strain and temperature on a single fiber sensor. Physically, both factors change the wavelength of the reflected light in similar ways. Without AI, you usually need two separate sensors to compensate. With a well-trained model, I could feed the raw spectral data into a neural net, and it successfully decoupled the two variables with 99% accuracy. This reduces hardware cost and complexity significantly.

This integration is crucial for Robotics News. Imagine a robotic arm with skin made of optical fibers. The AI doesn’t just feel “touch”; it can analyze the texture, temperature, and pressure simultaneously by decoding the complex light patterns scattering back from thousands of micro-printed sensors.

Medical Applications: Going Inside the Body

The implications for healthcare blow my mind. I often read Health & BioAI Gadgets News, and the trend has been towards non-invasive wearables. But sometimes, you need to go inside. The problem has always been size. You can’t shove a battery-powered sensor into a small capillary.

With these glass-on-fiber sensors, the “wire” is a thin strand of glass, and the sensor is microscopic. I’ve seen concepts where these are used to measure blood pressure inside a valve of the heart, or to detect specific biomarkers in the bloodstream in real-time. Because the sensor is 3D printed, it can be shaped to interact with specific proteins or cells.

I anticipate that by mid-2026, we will see AI Personal Robots News and surgical assistants utilizing these sensors for haptic feedback during microsurgery. If a robot is operating on an eye or a nerve, it needs to sense forces in the micronewton range. Traditional load cells are too big and numb. A 3D-printed spring on a fiber tip is perfect.

Industrial IoT and Infrastructure

Switching gears to heavy industry, this technology solves a massive headache I’ve encountered in the field: cabling and power. In Smart City / Infrastructure AI Gadgets News, we talk about “smart bridges” or “smart grids,” but wiring a bridge with thousands of electrical sensors is a nightmare of copper and corrosion.

Optical fibers are cheap, lightweight, and can run for kilometers without needing a signal boost. Now that we can print the sensor directly on the fiber tip, we can embed them into concrete, composite materials, or even 3D printed metal parts.

I’m particularly interested in Autonomous Vehicles News. EVs have massive battery packs that need thermal monitoring. Running copper wires inside a high-voltage battery pack is risky. Running glass fibers? perfectly safe. You can print temperature sensors on fibers and snake them between every single cell. The AI battery management system gets granular data on thermal runaways before they happen, without adding electrical noise or fire risk.

The Intersection with Consumer Tech

While this sounds very industrial, it’s bleeding into consumer tech faster than I expected. I’ve been looking at Wearables News and seeing patents for smart fabrics that use optical sensing. If you weave optical fibers into a shirt, and those fibers have microscopic motion sensors printed on them, you have a garment that captures full-body motion capture without bulky IMUs (Inertial Measurement Units).

This connects directly to AI in Fashion / Wearable Tech News. I can imagine a running shirt that analyzes your gait efficiency not by using a pod on your shoe, but by sensing the stretch and compression of the fabric itself across your back and shoulders. The data fidelity from optical strain sensing is orders of magnitude higher than capacitive fabrics.

Even in the home, Smart Home AI News could get a refresh. Current motion sensors are distinct white boxes in the corner of a room. Optical sensing could be embedded in the wallpaper or the floorboards. I’ve seen demonstrations where a fiber optic cable laid under a carpet could track the location of people walking, detect a fall, or even identify who is walking based on their footfall cadence—all processed by a local AI unit.

Challenges I’m Seeing

I don’t want to paint a perfect picture; there are real hurdles here. The biggest one I run into is fragility during installation. While the glass sensor itself is tough, the junction between the fiber and the real world is delicate. I’ve snapped more fibers than I care to admit. Connectors are still the weak point.

Another issue is the “interrogator” unit. The sensor is cheap (sand and light), but the box that sends the laser and reads the reflection is still expensive. We need AI Sensors & IoT News to start covering the miniaturization of the readout electronics. Until I can buy a $50 optical interrogator chip to plug into a Raspberry Pi, this will remain in the realm of high-end industrial and medical tech.

There is also the data volume problem. Optical sensors can sample at megahertz rates. If you have a thousand sensors in a smart building, you are generating terabytes of data. We need better AI Tools for Creators and engineers to manage this pipeline. We can’t send all that to the cloud. It mandates robust edge computing.

The Broader Ecosystem

It’s fascinating to see how this specific innovation ripples out to other categories. In Drones & AI News, lighter sensors mean longer flight times. A gram saved on wiring and shielding is a gram gained in battery.

In AI Gardening / Farming Gadgets News, I can see soil sensors that don’t corrode. You could leave an optical pH sensor in the ground for ten years, and it wouldn’t drift or degrade like an electrochemical one. The AI would simply adjust for any bio-fouling on the lens.

Even AI Toys & Entertainment Gadgets News might see a shift. High-fidelity haptics in VR gloves currently rely on bulky motors and sensors. Optical sensing could make haptic gloves as thin as silk, tracking finger movements with sub-millimeter precision.

Looking Ahead to 2026 and Beyond

So, where is this going? I suspect that throughout 2026, we will see the first commercial “development kits” for this technology. Right now, it’s mostly custom lab work. But once a company releases a “printer” that can attach to standard fiber spools, the floodgates will open.

I am keeping a close watch on AI Security Gadgets News as well. Passive optical listening devices are a scary but real possibility with this tech. If a fiber in the wall can act as a microphone because of a micro-printed membrane, privacy becomes a massive new conversation.

For those of us building the future of IoT, the message is clear: stop thinking about sensors as chips you solder onto a board. Start thinking of them as structural elements of the material itself. The line between the object and the sensor is dissolving.

I’m preparing my lab for this. I’m learning more about photonics and less about voltage dividers. If you are in the hardware game, I suggest you do the same. The future isn’t electric; it’s illuminated.